You are here:home > Quenching series > Pruduct's Detail

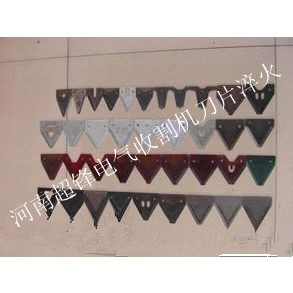

High frequency heat treatment furnace rotary blade

Rotary blade quenching furnace along with modern high-tech,the friends of farmers farming, cultivated land, plowing,harvesting…… Have become to as the Yellow Crane, it is necessary to hardware tool heat treatment that is notchoosing efficient, how not only, what force, but also improve the higher demand for the task, specializedproduction economic and environment-friendly, cost-effective quenching equipment and suitable selection of Henan super Feng electrical equipment limited company withyou more the benefits! The product details call advisory business down to ask for friends patronage patronize!

Rotary blade high frequency furnace and application:

Quenching treatment 1, seamed pipe wall, concrete inner wall quenching, quenching machine tool;

Welding cutting tooth 2, coal mine;

Welding the word bit and plum bit 3, mine;

4, the diameter below 30 bolts of hot deformation;

The nut 5, diameter 30 following hot deformation;

6, metal powder melting;

Heat treatment 7, 300 the following chain wheel diameter;

Quenching processing 8, 80 the following axis diameter;

Section 9, 80 the following processing diameter ofworkpiece;

Quenching treatment 10, a variety of handmade things(hammer, axe, pliers, wire clippers);

11, all kinds of automotive equipment (such as the thermal deformation of the socket wrench);

12, automobile, motorcycle parts are part of the heat treatment;

13, all kinds of machine parts to punish a small heat treatment (manufacturers need to provide drawings and Wu Yi)

Rotary blade quenching machine high frequency furnace spinning technology advantage:

1) circuit change little root to practice, because theadmission of new power device, circuit and technology has got great development;

2) device power rectifier and inverter circuit adoptingmodule device instead of a power device. In order to achieve greater power, accepted the power devicecommunication, parallel or series parallel;

3) control circuit and care circuit much adoption ofdigital integrated circuits, ASIC, simplifying the circuitand improve the reliability of the system;

4) the new circuit element, such as non inductive capacitormodule, non inductive resistance, power ferrite use;

5) frequency range is broad, from 0.1 – 400kHz covering the frequency range, high frequency, ultra audio;

6) conversion yield high, obvious energy saving. Take thetransistor inverter load power factor is close to 1, canreduce the input power of 22% – 30), 44% – 70% reduction of cooling water;

7) the whole device connected with the electrical layout,equipped with CF can save 66% - 84% of the space;

8) concerned with the circuit successfully, high reliability;

9) internal power supply, output low, high safety.

Tags: on-product information